General Connection Modes

Two connection modes exist: Human-to-Machine and Machine-to-Machine/EDI (a combination is possible).

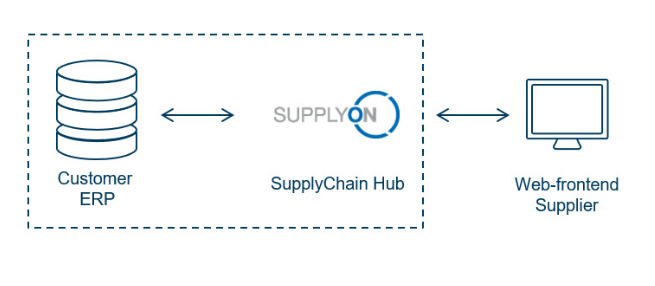

Connection via Internet browser (H2M)

All you need for an H2M (Human TO Machine) connection is a computer or a tablet, a browser and Internet access. As a registered user, you receive your customers' EDI messages as a SupplyOn web form. You can also send the data back via the browser - your customer receives it as an EDI message.

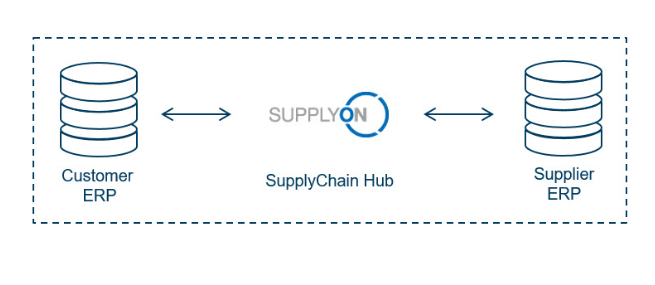

Connection via EDI (M2M)

With an M2M connection (Machine TO Machine), you can integrate automatic data exchange. To implement the relevant business processes, you need a specific connection and assignment between your ERP system and SupplyOn. You can choose between two communication channels: OFTP2 or AS2 via a secure Internet connection.

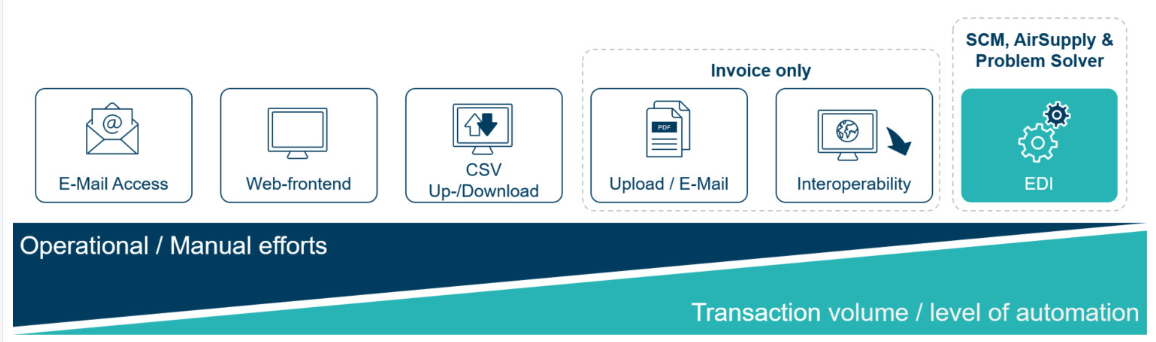

SupplyOn offers various channels to exchange collaboration data

M2M/EDI mode is recommended in case of high data volume exchanged between customers and supplier. The supplier manages its project with SupplyOn.

EDI options

| Application | AS2 | OFTP2 | HTTPS | Message formats |

|---|---|---|---|---|

| Supply Chain Collaboration | X | X | X | EDIFACT format and VDA container for attachments |

| AirSupply | X | n/a | n/a | BoostAero XML or AirSupply CSV |

| Invoicing | X | X | n/a | UBL XML or EDIFACT with VDA container for attachments |

| Problem Solver | X | n/a | X | SupplyOn QDX XML format |

Checklist - Find out if you can use our EDI service or not

Are you already EDI-enabled? Does direct data exchange via your ERP system benefit you? ... Or is the web-based solution more suitable?

If you can answer the questions with "Yes", then EDI fits for you.